HeatTek has decades of experience engineering, fabricating, and commissioning impregnation systems of all types. Our goal is to supply quality systems, focusing on the customer’s staff and facilities, resin selection, and process requirements. HeatTek will provide all aspects of the system design, as well as manufacture, install, commission, and service the system. We also offer spare parts for all impregnation equipment.

Benefits of Vacuum Pressure Impregnation (VPI) Equipment

There are several benefits to using VPI equipment for impregnating porous materials with resin or other impregnating fluids. Here are some of the benefits:

- Enhanced Electrical Insulation: VPI equipment is used to impregnate electrical components like transformers, generators, and motors. Electrical insulation is improved through the elimination of air voids and increasing the dielectric strength of the material.

- Increased Thermal Conductivity: VPI systems improve the thermal conductivity of materials by filling voids with thermally conductive resins/fluids.

- Corrosion Resistance: Impregnating materials with corrosion-resistant compounds, protects them from harsh environmental conditions.

- Extended Lifespan: With high-quality materials and corrosion resistance, the lifespan of these materials can be extended.

- Range of Applications: VPI systems provide a versatile process that can be utilized for different materials and applications ranging from aerospace and automotive to electrical engineering.

We look forward to the opportunity to meet with you to discuss our impregnation equipment. Contact HeatTek today to discuss your project requirements and get a comprehensive quote.

Vacuum Pressure Impregnation (VPI) Types

Dip Tanks

HeatTek offers custom and pre-designed dip tanks for any application. Our custom dip tanks can be designed to meet your exact requirements.

View More

Dip Tank Impregnation Systems

Features for these systems include carbon steel construction, reinforced cover, and NFPA Standards compliance.

View More

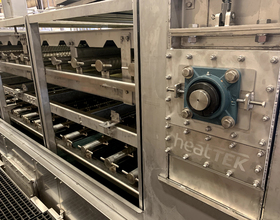

Vacuum Only Impregnation (VOI) Systems

We offer vacuum only impregnation (VOI) systems engineered to meet production needs as well as the use of current part racks.

View More

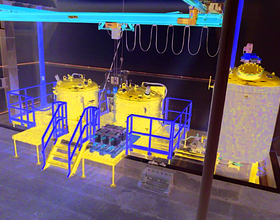

Vacuum Pressure Impregnation

We offer systems ranging in size from 2-12 ft. in diameter in a range of options to meet your needs.

View More

Vacuum Pressure Impregnation

We offer systems ranging in size from 2-12 ft. in diameter in a range of options to meet your needs.

View More

Retrofits and Rebuilds - Metal Packaging Equipment

HeatTek has developed innovative, cost-effective solutions for a wide range of heat treat applications including Bottom Furnaces, Horizontal Quench Furnaces, Quench Tanks, Air Quenches and Aluminum Aging Ovens.

View More