What Is a Coolant Filtration System?

Traditional soluble oil filtration systems collect, filter, temperature balance, and recirculate new and used coolants (soluble oil) for bodymaker operations. This process requires large tanks, heat exchangers, filter cartridges, and pumps, not to mention extensive piping and valve components. These filtration system can successfully remove debris and fine particles that get mixed in the coolant during honing, lapping and polishing.

Why Mobile?

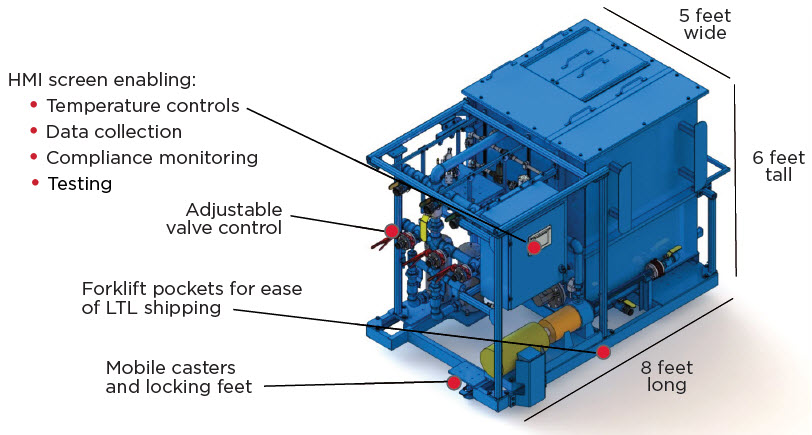

Mobile coolant filtration systems carry out the same process but serve a unique purpose. Designed for up to three body-makers, they give canmakers freedom instead of costly downtime. Mobile coolant filtration systems use advanced engineering techniques and state-of-the-art technology to accomplish the same process as the full scale version with a drastically reduced footprint and full mobility.

When a canmaker is building a new can line, there's no longer a need to wait for the full production plant coolant filtration system to come online. Instead, the bodymakers' pre-production field testing can be done with the mobile unit. This will cut line start-up time significantly.

Additionally, when a plant is testing a new coolant or doing any project that requires the oil filtration process, they would normally need to halt production on the existing line to utilize the existing full-scale filtration system during testing and QA. The mobile unit would allow it to happen independently of normal production.

With its size and ability to be shipped via LTL, a mobile coolant filtration system can even be shared among plants. The unit also requires minimal maintenance with a simple flush process and easily accessible filters and valves.

Operational Flexibility

Mobile coolant filtration systems offer unparalleled flexibility. The design supports a wide range of canmaking operations as well as any number of pre-determined recipes.

And with optimized hydrominders, the auto make-up system provides level sensor feedback.

Another key advancement with HeatTek’s mobile coolant filtration system is the ability to see detailed information on coolant makeup. Instead of requiring technicians to manually sample the blend of cup lube, neat oil, and gear oil, high-tech sensors show the current ratio in real-time. This allows for time- and labor-saving adjustments.

Customizability

All specifications can be customized to each plant’s requirements. If canmakers need specific configurations, HMI capabilities or even a different footprint, HeatTek can partner with them to accomplish their goals.

See High-Tech Coolant Filtration in Action

HeatTek is a global leader in industrial manufacturing equipment. For more than 20 years, our expert team has engineered, installed, maintained, and retrofitted can production systems, such as washers, dryers, and bake ovens. Contact us for detailed information on our revolutionary mobile coolant filtration system.